Working principle: The core components of the JTM colloid mill are composed of a multi-stage rotor (grinding disc) and a stator (fixed grinding disc). Its design refers to international best practices and presents a grinding effect with increasing precision from the center to the periphery. The rotor rotates at high speed driven by the motor, and the medium enters the grinding zone under the action of mechanical movement and centrifugal force. There are thousands of teeth on the rotor and stator, and the flow channels are distributed radially. The width, position, angle and radial depth of the grooves of the grinding disc are constantly changing, resulting in changes in the direction and instantaneous speed of the medium at each grinding stage. The medium is subjected to millions of rapid and intense shearing, friction, compression and kneading, resulting in the breakage of the original molecular chain, and the various media are recombined at the molecular level to form new molecular chains.

Product use conditions:

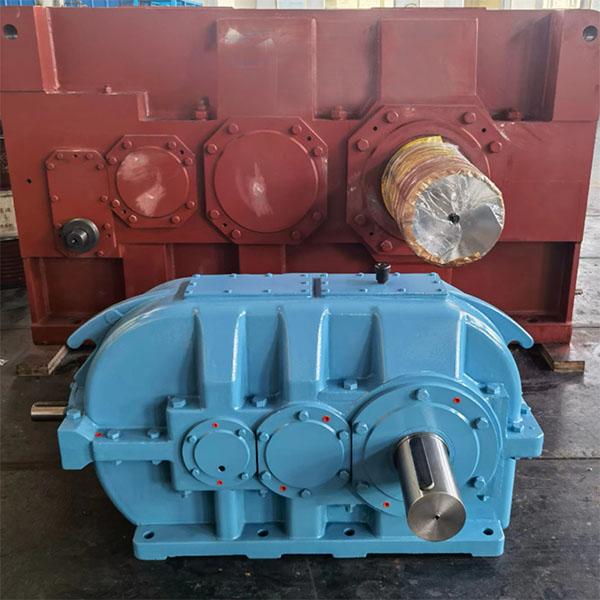

ZQA type reducer is mainly used in material handling, mining, chemical, textile, light industry and other industries. Its use conditions are as follows:

- The circumferential transmission speed of the reducer is not more than 16 m/s.

- The speed of the high-speed shaft of the reducer is not more than 1500 rpm.

- The working environment temperature of the reducer is -40°C to +45°C.

- The reducer can run forward and reverse.